Vladka Kozáková is a manager who has worked for 16 years in a Canadian company and seven years in a global role at the Toronto Headquarters. She is currently responsible for Human Resources in a global company and is based in Rome as Vice President Global HR & Sustainability at Yokohama TWS, a company operating in over 50 countries.

You work for a global company that is designing tyres and wheels for the future. So, what is the future of tyres in the context of electromobility?

At Yokohama TWS we have been designing and delivering tyre & wheel solutions and services for the off-highway tyre industry for decades, working in the Agriculture, Material Handling, Construction and Two-Wheeler markets.

We are constantly looking to stay ahead when it comes to vehicle innovations and materials used to power them. And this is the case with the arrival of e-vehicles and the consumer demand for more sustainable solutions: our engineers develop, test and manufacture new tyres, wheels and even digital solutions that give our customers new ways to improve their operations – and their businesses.

Agribusiness, for example, is undergoing a major transition toward more sustainable farming, with farmers looking for better ground and crop protection, greater efficiencies and longer lasting tyres. At the same time, electric vehicles are being used more and more. As a result, we introduced our most sustainable tyre ever, the Trelleborg TM1 ECO POWER tyre, engineered for the new generation of electric tractors. This tyre lets farmers see significant savings in fuel or battery consumption and it is made from 65% recycled and biobased materials. This tyre is in fact a testament to our ongoing commitment to being a part of the solution for a more productive and sustainable future. Indeed, across all facets of our business, we’re working on decreasing fossil fuel dependency and increasing product circularity, while at the same time improving our customers’ operations. And that’s what we mean by offering tyres designed for the future.

In the group, you deal with human resources on a global level. Is there a difference compared to the Czech Republic?

Global human resources can be described as “same, same but different”. Our people are the real differentiator and our competitive advantage. We value our people from all aspects, their diversity, opinions, skills and capabilities, their talents, ideas, and uniqueness.

We live “People First” culture. It means for us a clear understanding that business is done by people: our customers, suppliers, our employees, local authorities, all of us are people. So, we are very much focused on the human aspect of business. People want to be appreciated and treated fairly – and it is the same everywhere.

We operate in more than 50 countries globally, so for sure we find many local differences such as the local employment standards and laws, culture differences, also different ways of thinking and talking and I do not mean a language difference at this moment, but a different mind-set.

I have been in a global role for more than 15 years, and I can say that every country and every nationality have its own characteristics, Czech people as well, but mutual respect, human approach and fairness is appreciated everywhere.

Sustainability in company behaviour is not only a necessity, but also one of your values. What does this value include?

When it comes to sustainability our values can be seen in our philosophy that permeates our entire company: “Our behaviour embraces the future”. And our behaviour starts with ensuring sustainability across our entire business, from our manufacturing processes designed to minimize the impact of our global operations to the careful selection of recycled resources and biobased materials for our tyres, to engineering longer lasting, fuel-efficient tyres.

After all, the way we act and run our processes – from steampowered production plants to smart connected tyres that reduce waste and help businesses keep their vehicles running more efficiently – is our way of showing customers and their communities that they, too, can take a more sustainable approach, for a better future for all.

Moreover, as one of our principal core values, all of us at Yokohama TWS believe it’s important to give back to the communities where we operate. Our teams take initiative through our People First Employee volunteering programs and our Social Engagement activities.

It seems that a tyre is always the same product. What is the basis for innovation and digitalisation in your company?

We have a Global Technology & Innovation team conducting cutting edge research and development to design and deliver our tires of the future. We combine new technologies with more sustainable solutions to create innovations that make sure our customers are more productive, more efficient, and more sustainable than ever before.

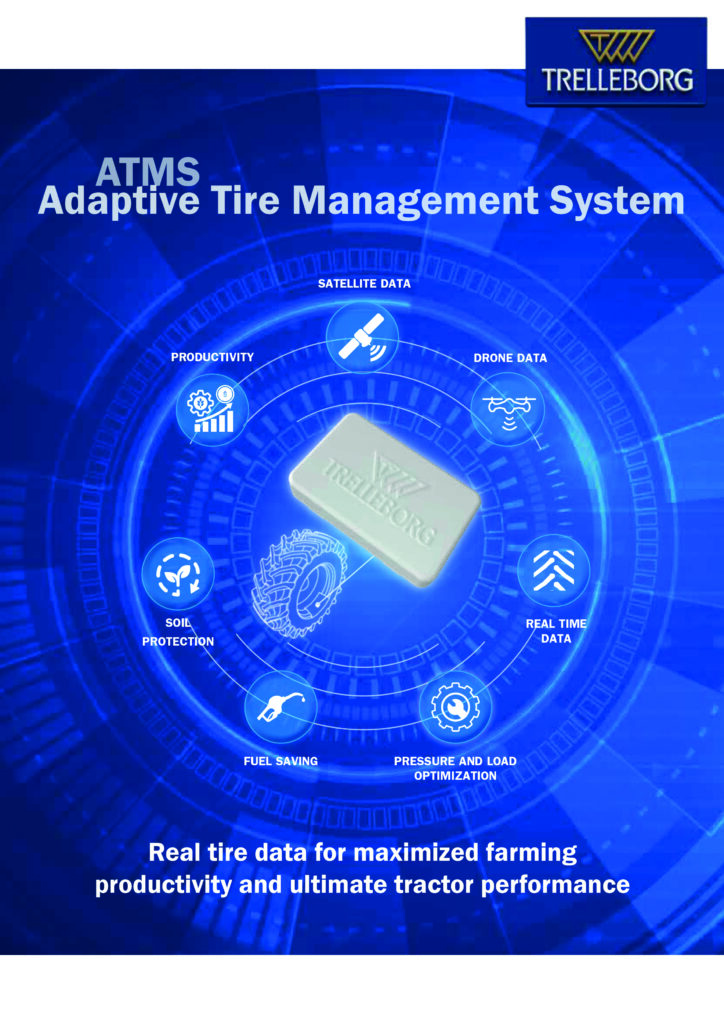

Breaking it down into specific industries, tyre innovations help propel vehicle performance. In Agriculture, besides innovation in tire compounds, we have developed the Trelleborg ATMS – Adaptive Tyre Management System. Tyre-mounted sensors give farmers real-time data for ultimate tractor performance no matter the job. This means farmers and fleet operators can count on smart farming tech to improve their everyday operations.

We’ve developed a similar solution for the Construction industry, where there is greater focus on predictive maintenance, safety, and machine performance. We rolled out the Trelleborg TPMS – Tyre Pressure Monitoring System, a cloud-based system integrating tyre sensors, a central command center on the vehicle and an online platform to increase operational efficiency – so managers can make sure their machinery is running more smoothly while monitoring their performance right from their desks.

For Material Handling, the Trelleborg XP tyre range offers super solid forklift tyres with advanced technology in tread design and longer-lasting tyre compounds for optimal performance in each specific working condition. The XP1000 tyre, in particular, features the Trelleborg’s Pit Stop Line, an orange strip that appears when it is the right time to replace the tyre – again, helping operators maximize usage and reduce waste. Once you delve deeper, tyre solutions are much more than a simple combination of rubber and steel.

Thank you for the interview.